- All Categories

- Sealers and Chemical Joints

- Adhesives and Stickers

- Glues

- Cleaners and Solvents

- Lubricants

- Primers and Lacquers

- Putties

- Additives/Auto

- Additives/Building

- Electrical Protection

- Adhesive Tapes

- Waterproofing

- Packaging, tubes and accessories

- Motorcycles

- Surface Treatments

- Metrics Screws

- Nuts and Washers

- Tapping Thread Screws

- Woods Screws

- Screws For Metal and PVC

- Rivets and rivet nuts

- Staples and Nails

- Eye Bolts and square bend hooks

- Pins

- Cutting and Grinding Discs

- Drill bits

- Grinders and Countersinks

- Crowns

- Saws

- Taps and Dies

- Thread Repair

- Windscreen Removal Blades

- Abrasive Discs

- Sandpaper in Roll

- Sandpaper in Band

- Abrasive Brushes and Grinding Wheels

- Clamps

- Gasoline Pipe PVC Pipe

- Sealing Washers

- Crankcase Plugs

- Tyres (Counterweights/Valves and Patches)

- Bellows

- Exhaust Supports

- Lubricants Plastic Union

- Block Plugs

- Tyre Valve core

- Wheel counterweights

- Wiper Blades

- Bulbs

- Vehicle staples

- Underbody Protection

- Protective Masking

- Glass Repair

- Vehicle Repainting

- Interior Repair Kits

- Exterior Repair Kits

- Caravan Kit

- Bodywork Accessories

- Bodywork Utensils

- Terminals

- Electricity Complements

- Acessórios de Eletricidade

- Ties/ Cable Fixing

- Terminals

- Connectors

- Fuses

- Strip terminals

- Sheath cables

- Lighting

- Low Load Anchors

- Medium Load Anchors

- Heavy Load Anchors

- Chemical Anchors

- Hinges

- Guides

- Profiles and supports

- Insulation

- Bolts and hinges

- Soft Solder

- Electrodes

- Welding Equipment

- Chemicals for Welding

- Rebar

- Formwork

- Railings and Stairs

- Trowels, Steel Grout, Cubes

- Construction Tools

- Flooring and Tiling

- Construction Machinery

- Painting accessories

- Personal Cleaning

- Eye protection

- Masks/Goggles/Helmets

- Respiratory protection

- Hearing protection

- Footwear

- Gloves

- Workwear

- Exterior Protection/Signage

- Signaling

- Various protections

- Screwdrivers and Bits

- Spanners

- Pliers and Pincers

- Impact Socket/ Ratchet

- Hammer Tools

- Files

- Callipers and Clamps

- Tools For Electricity

- Sanitary Tools

- Car Repair Equipment

- VDE Tools

- Anti-Spark Tool

- Aplications Guns

- Greasing

- ESD Tool

- Vernier Caliper and Micrometers

- Metric Tapes

- Laser Systems

- Measurement Angles/Levels and Telescopic Ruler

- Torque Control

- Jars and Funnels

- Various Testers

- Inspection Equipment

- Compressed Air

- Tool Trolleys

- Tool Boxes

- Benches, Tables and Stands

- Lighting

- Lifting

- Industrial accessories

- Cleaning. rags, cloths and absorbents

- Cleaning. paper and paper dispensers

- Cleaning. Complements

- Industrial accessories

- Pneumatic

- Electrical

- Duss

- Drilling System

- Other Machines

- Milwaukee

- Air Brake System

- Signage/Lighting

- Electrical System

- Lashing sistems/ Safety

- Mechanical

- Industrial Vehicle Accessories

- Couplings VIN

- Cleaning Items

- Industrial Accessories

- Supports and Accessories

- Threaded rod and fixing accessories

- Metal cable ties

- Plastic cable ties

- Steel wire rope fastening

- Showers and sanitary accessories

- Fixing for A.C. and radiators

- Car Wash Chemicals

- Car Wash Accessories and Complements

- Car Wash Machines

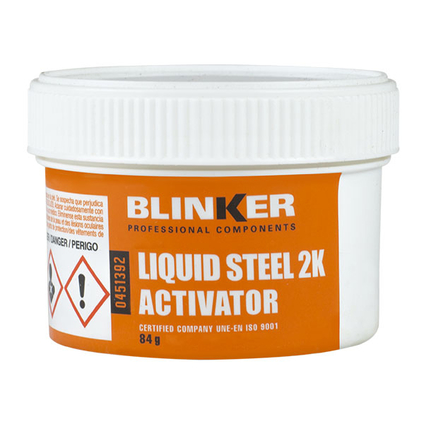

Liquid steel 2k

SEE FULL DESCRIPTION

FREE RETURNS

SAFE PURCHASE | ISO9001

DELIVERY IN 48H. - PRIORITY SHIPPING

MORE THAN 20.000 PRODUCTS

| Reference | Description | Quantity | Quantity | |

|---|---|---|---|---|

| 0451392 | LIQUID STEEL 2K 500G | |||

| Contact | ||||